Table of Contents

What is IPC Class? - IPC Class meaning

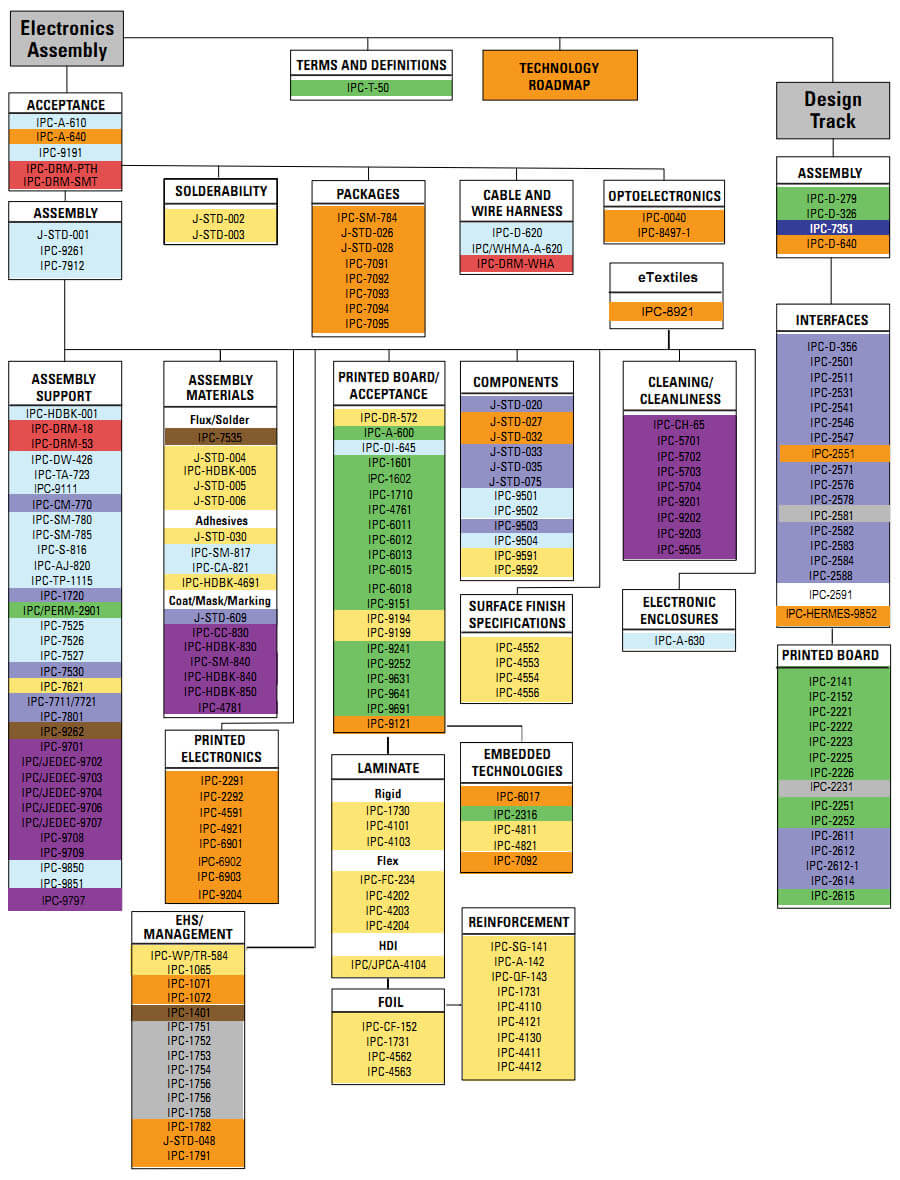

IPC stands for Institute of Printing Circuits and belongs to the trade electronic interconnection industry. IPC officially provides PCB-related Classes and is now also known as the Association for Connecting the Electronics Industry. IPC is an international industry composed of more than 4000 companies, which participate in the use, designation and design of printed circuit boards and components, including advanced microelectronics, military applications, aerospace, automotive industry, computer, industrial and medical equipment, and telecommunications.

Security, reliability, and high performance are required for PCB-related products. Quality, attention and commitment must be maintained throughout the production process. To meet user/customer specifications and expectations, many PCB production industries use these classes to maintain consistency, high reliability, high quality, and commitment. These also help to improve the process of PCB products in many ways.

IPC Class Requirements in PCB Production

- Acquire final product control of high quality and reliability.

- Improve communication with many employees and suppliers.

- Reduce the cost of PCB.

- Raise your reputation and create new opportunities.

Terms in the IPC Class include

- Acceptance test: Check whether the product is up to standard according to the requirements of PCB user or buyer or seller.

- Assembly: Include connections or assemblies of various parts, and assembly together.

- Anti-corrosive agent: plays a role in protecting the coating material of the product during the manufacturing and testing processes such as electroplating, etching, welding, etc.

- Integrated Circuits (IC): Various electronic circuits are interconnected in one place with a material to perform the required functions according to the application.

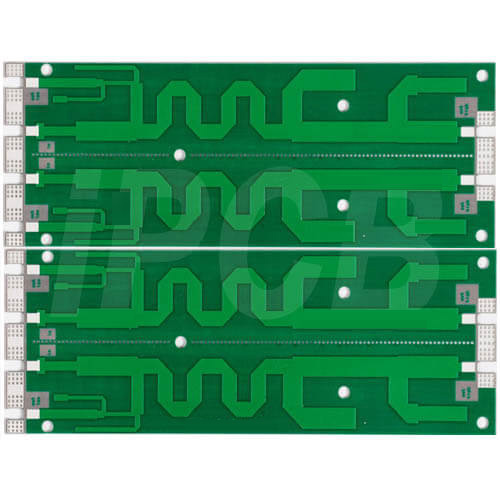

- Elastic strength: refers to the tensile strength of the material fibers, which can be bent, folded or rotated.

- Key operations: refers to the complete operation, process and characteristics of the product.

These Classes are suitable for three types of electronic products related to printed circuit boards.

- Type 1: General PCB related electronic products. This type of product is a daily-use product, mainly used to complete the integrated functions.

- Type 2: Service electronics (exclusive). It refers to the high performance, high reliability and long life of the product. Uninterrupted services are preferred for an end-use environment that will not cause any damage.

- Type 3: High performance electronics. Refers to continuous and on-demand performance. Since there is no downtime device, it should work when needed. Ultimately, the environment can be harsh and related products are used as life support systems.

Some PCB Class examples in PCB design and production are IPC-2581, IPC-2221, IPC-4101C, IPC-6012B, IPC-A-600F, J-STD-001, IPC-A-610, IPC-A-620, IPC-TM-650, etc.

Welded IPC Class is necessary for the manufacture of PCB and PCB products. In the global industry, IPC ClassIPC-J-STD-001 G is used for welding materials and processing. The IPC-J-STD-001 Training and Certification Program applies to the welding of electrical and electronic components during manufacturing.

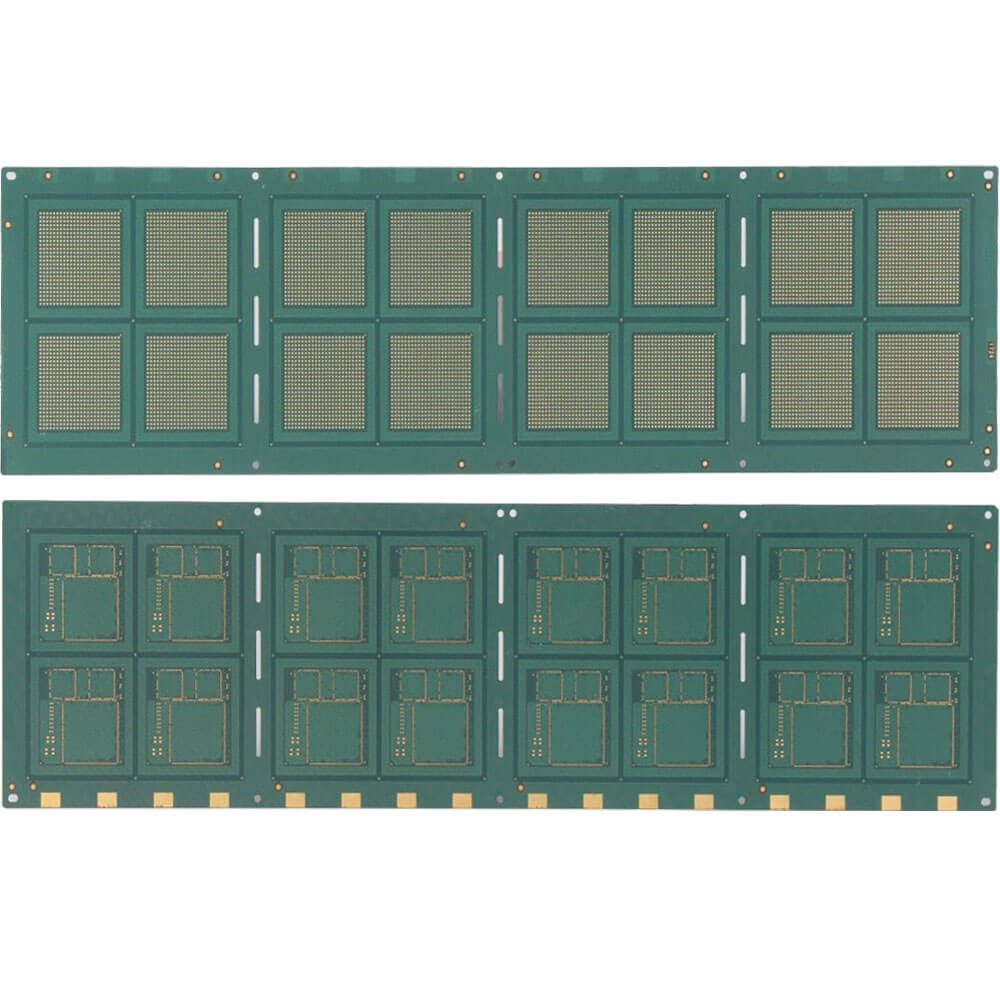

In the modern electronics industry, PCB is designed and manufactured using IPC Class with quality, consistency and lass processes. Basically, the IPC-7350 Series Class is used in the physical design of printed circuit boards of different types and specifications. These Classes help maintain high quality, reliability, performance, time, cost, and waste during manufacturing.

In the design of a PCB, it is also necessary to check that the components are properly mounted on the surface. Otherwise, additional costs may be incurred in designing and using specific components.

IPC Class is not always used to design components on PCBs. A software package called CAD tools makes it easy to design PCBs, components, and strategies. According to the user’s requirements, PCB components are designed with two-dimensional and three-dimensional CAD tools.

These Classes are suitable for three types of electronic products related to printed circuit boards.

- IPC Class1 is assigned to general purpose circuit boards with limited life and simple functions, including those products whose main requirements are complete component functions. As long as the function of the circuit board is not affected, IPC Class1 circuit board is allowed to have various appearance defects. In these types of circuit boards, product reliability is not a key factor. For example, they can be found in TV remote control, LED lights, children's toys, etc. They are the lowest cost circuit boards in the industry, but their life expectancy is limited.

- IPC Class2 is used for dedicated service electronics. This means that you want the circuit board to have a longer life so that you can place it in a TV, computer, or air conditioner. Including those products that require continuous operation and long service life. It is better to keep working without interruption, but the requirements are not strict. IPC Class2 products will not be exposed to extreme environmental conditions. Generally, it will not cause failure due to the use environment. The IPC Class2 circuit board has higher reliability and longer life. They follow stricter standards than IPC Class1, but some appearance defects are allowed.

- IPC Class3 is used for products with continuous high performance or performance on demand is critical, product downtime cannot be tolerated, the final use environment may be extremely harsh, and the product must play a role when needed. Moreover, the use environment of the final product is extremely harsh, and the product must be able to operate normally when required. The IPC Class3 circuit board has been inspected and tested at a high level according to strict standards. This makes the grade 3 plate highly reliable. This category includes life support system, military equipment, electronic monitoring system, automobile PCB and other key systems, life-saving equipment or other key systems.

IPC-6012DS 3A Class

IPC-6012DS 3A Class is a relatively new class. We sometimes call it IPC Class 4, including space and military avionics. This is the highest level of printed circuits. 3/Class A plates require very strict manufacturing standards, because the plates should remain operational under critical conditions such as outer space. These plates are expensive to manufacture compared to other grades because they need to be close to perfection. They exist in aerospace, military airborne systems and missile systems.

PCB manufacturers typically use IPC-A-610 Class2 or a more advanced IPC-A-610 Class3 as the PCB manufacturing standard. IPCB supports both IPC-A-610 Class2 and IPC-A-610 Class3.

What is the difference between IPC Class2 vs IPC Class3? Please click to refer to this document – IPC-Class2-vs-IPC-Class3.pdf

If you need to know the requirements of IPC-A-600 in detail, please click Download – IPC-A-600G.pdf

iPCB is a professional PCB manufacturer. We provide high-quality PCBs that meets IPC standards.

Once the inspection process has been completed, KLARF will be produced to show all the findings. This is what will determine whether or not a PCB has been built according to stipulated standards within the electronic industry.

High frequency PCB

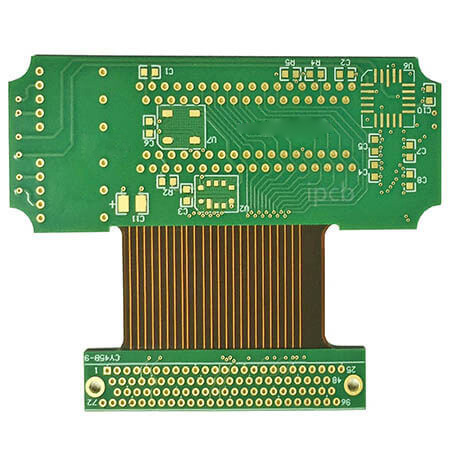

Rigid-Flex PCB

Teflon PCB

Halogen-Free PCB

HDI PCB